HTM Series Virtual Y Axis CNC Turn Mill

CNC lathe is one of the widely used CNC machine tools. It is mainly used for cutting the inner and outer cylindrical surfaces of shaft or disc parts, inner and outer conical surfaces with arbitrary cone angles, complex rotating inner and outer surfaces, cylindrical and conical threads, and can perform groove cutting, drilling, expanding, reaming, and boring.

Category:

Keyword:

CNC Turn Mill

Details

Product Features

● The main components of the machine tool are all made of high-quality resin sand molding, high-strength and high-quality cast iron, with a complete heat treatment process to eliminate residual stress, and sufficient reinforcing ribs are arranged to ensure that the entire machine has sufficient strength, rigidity, and high stability. All have undergone three-dimensional analysis processing.

●The spindle adopts permanent magnet synchronous spindle direct drive, which has the advantages of sensitive driving, stable output torque, high smoothness, fast positioning, high speed, low noise, and other characteristics. The base adopts double-layer isolation technology to prevent high-pressure water leakage.

●The machine tool adopts modular design, which can quickly achieve automation devices and meet various customer needs.

●Adopting a withdrawable coolant tank for easy cleaning of chips.

●Wide selection range: such as feeder, feeder, tool setting device, and the second spindle can be high-speed docked with automated truss robots.

Rolling guide rail

The Z-axis adopts high-precision linear rolling guides to improve movement speed and greatly reduce non cutting time. The imported ball guide rail is used, with high positioning accuracy and less wear, which can maintain accuracy for a long time, fully improve productivity, and ensure its processing stability.

Virtual Y-axis turning and milling composite

The virtual Y-axis adopts two pairs of high-precision embedded steel guide rails to ensure the machining rigidity of the machine tool and the wear resistance of the guide rails, ensuring a long service life. The screw rod adopts a high-speed silent ball screw to improve the accuracy of the machine tool and ensure its machining stability. High positioning accuracy and low wear can maintain accuracy for a long time.

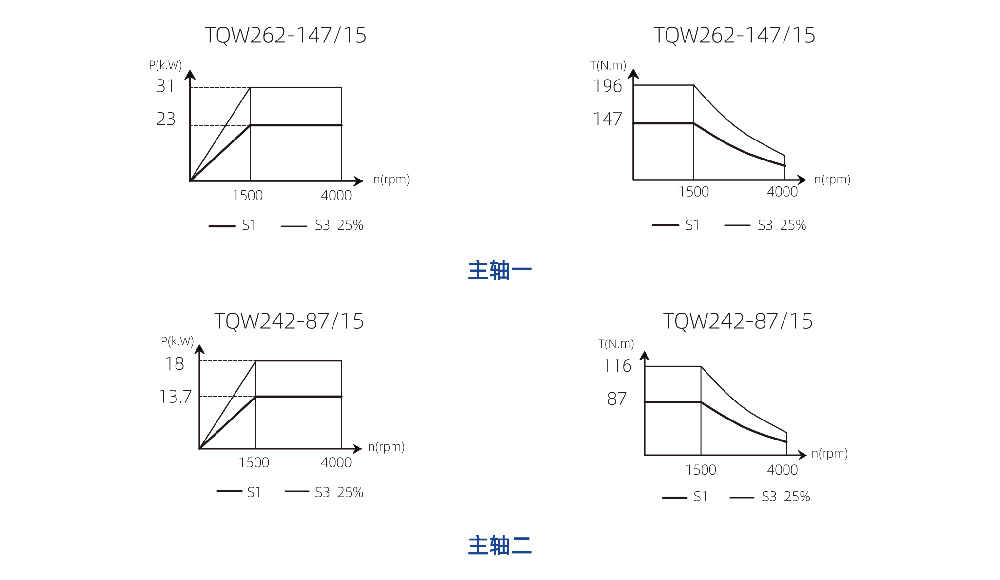

Spindle power torque diagram

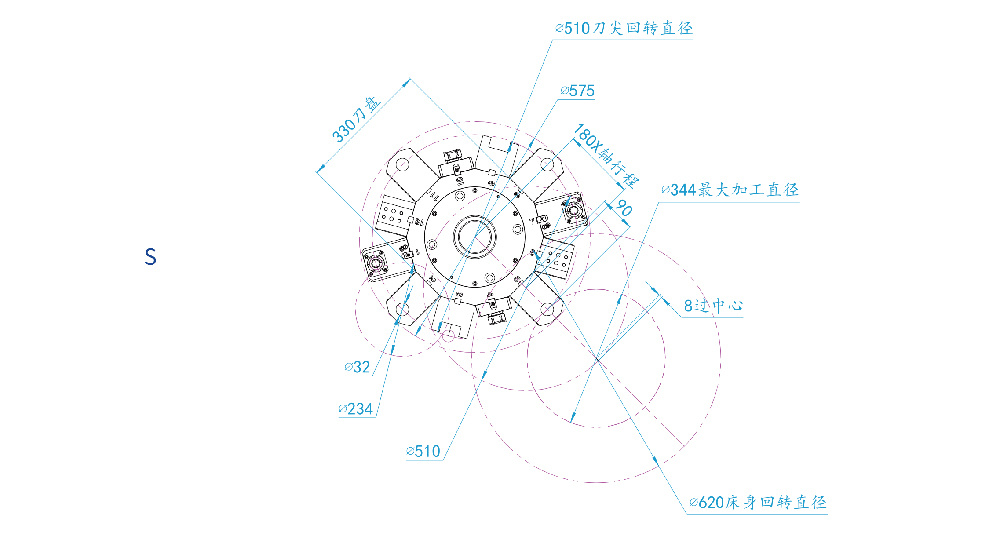

Tool interference diagram

Outline Dimensional Drawing

| Item | Unit | HTM06-SY | HTM06-ZY | HTM06-SD | HTM06-ZD | |

| Working Capacity |

Max swing dia.over bed | mm | Φ520 | Φ520 | Φ520 | Φ520 |

| Max.Turning Dia. | mm | Φ260 | Φ260 | Φ340 | Φ340 | |

| Max.Workpiece Length | mm | 580 | 580 | 580 | 580 | |

| Max.Bar dia. can processing | mm | Φ50 | Φ50 | Φ50 | Φ50 | |

| Spindle | Max. Spindle Speed | rpm | 4500 | 4500 | 4500 | 4500 |

| Spindle Nose Type | / | A2-6 | A2-6 | A2-6 | A2-6 | |

| Spindle Thru-Hole Dia. | mm | Φ62 | Φ62 | Φ62 | Φ62 | |

| Spindle Taper | KW | Metric 70 | Metric 70 | Metric 70 | Metric 70 | |

| Sub-Spindle | Max. Sub-Spindle Speed | rpm | 4500 | / | 4500 | / |

| Sub-Spindle Nose Type | / | A2-5 | / | A2-5 | / | |

| Sub-Spindle Thru-Hole Dia. | mm | Φ56 | / | Φ56 | / | |

| Sub-Spindle Taper | MT 6 | / | MT 6 | / | ||

| Tailstock | Tailstock Sleeve Taper | / | MT 5 | / | MT 5 | |

| Tailstock Sleeve Dia./Travel | mm | / | 125 | / | 125 | |

| XYZA Axis Travel | X / Z Axis Travel | mm | 211/500 | 211/500 | 211/500 | 211/500 |

| Y / A Axis Travel | mm | ±50 /606 | ±50 /606 | A 606 | A 606 | |

| Rapid federate(X/Z ) | m/min | 25/25 | 25/25 | 25/25 | 25/25 | |

| Rapid federate(Y/A ) | m/min | Y 12/A 30 | Y 12/A 30 | A 30 | A 30 | |

| Positioning accuracy(X/Z) | mm | 0.006 | 0.006 | 0.006 | 0.006 | |

| Positioning accuracy(Y/A) | mm | 0.008/0.006 | 0.008/0.006 | A 0.006 | A 0.006 | |

| Re-Positioning accuracy(X/Z) | mm | 0.004 | 0.004 | 0.004 | 0.004 | |

| Re-Positioning accuracy(Y/A) | mm | 0.006/0.004 | 0.006/0.004 | A 0.004 | A 0.004 | |

| Tool Turret | Tool No. | 12 | 12 | 12 | 12 | |

| External cylindrical turning tool Size | mm | 20×20 | 20×20 | 20×20 | 20×20 | |

| Tool Holder Size | mm | Φ40/Φ32 | Φ40/Φ32 | Φ40/Φ32 | Φ40/Φ32 | |

| Others | Machine Size(L×W×H) | mm | 2741×1861×1979 | 2741×1861×1979 | 2741×1861×1979 | 2741×1861×1979 |

| Machine Weight | KG | 6200 | 6150 | 6000 | 5950 | |

| CNC Controller | KND 2000 | Std. | Std. | Std. | Std. | |

| SYNTEC 21TA | Opt. | Opt. | Opt. | Opt. | ||

| FANUC/Siemens/Mitsubishi | Opt. | Opt. | Opt. | Opt. | ||

CNC lathe is one of the widely used CNC machine tools. It is mainly used for cutting the inner and outer cylindrical surfaces of shaft or disc parts, inner and outer conical surfaces with arbitrary cone angles, complex rotating inner and outer surfaces, cylindrical and conical threads, and can perform groove cutting, drilling, expanding, reaming, and boring.

Relevant information

这里是标题一h1占位文字

LEAVE US

A MESSAGE