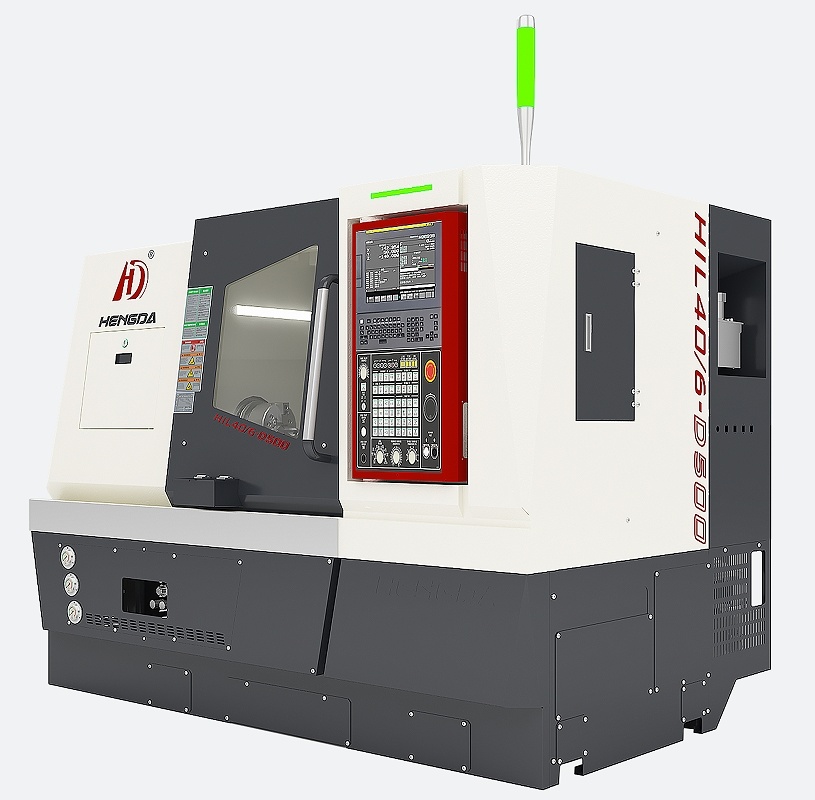

HIL40 Series Inclined bed CNC Lathe/CNC Turning Milling Machine

CNC lathe is one of the widely used CNC machine tools. It is mainly used for cutting the inner and outer cylindrical surfaces of shaft or disc parts, inner and outer conical surfaces with arbitrary cone angles, complex rotating inner and outer surfaces, cylindrical and conical threads, and can perform groove cutting, drilling, expanding, reaming, and boring.

Category:

Keyword:

Slant Bed CNC Turning Center

CNC Turn Mill

Details

HIL40 Series Inclined bed CNC Lathe/CNC Turning Milling Machine

Product characteristics

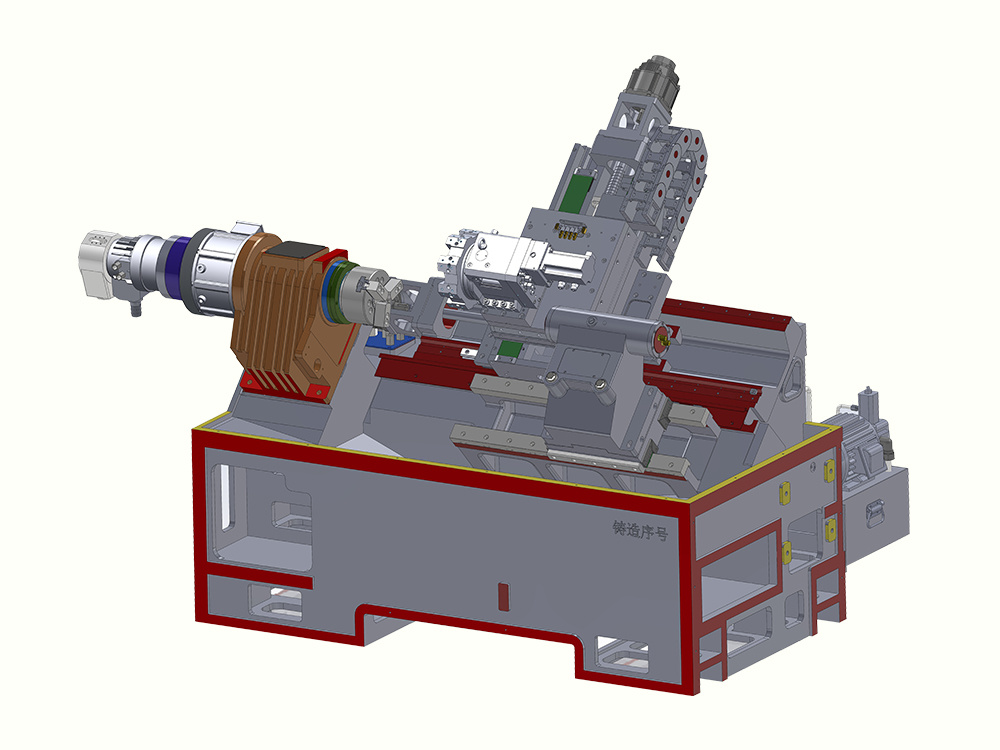

● 45° overall tilt bed design, high rigidity, more smooth chip removal.

● Finite element structure analysis, casting bar layout is reasonable, good force effect.

● The X/Y/Z axis screw is pre-drawn structure, which can reduce the influence of temperature rise on the screw accuracy during processing. The oil seal is added to the screw bearing protection at both sides of the screw, and the ball screw is silent.

● Tailframe adopts linear steel insert guide rail, heavy load rigidity, upper and lower layered structure, there is a micro adjustment device between the upper and lower layers, convenient for the tailframe center rotation center along the X axis direction fine tuning, standard with live center structure tailframe.

● HENGDA self-designed integrated permanent magnet synchronous headstock, low noise, high precision, long life, high finish, constant torque output, high C-axis positioning accuracy.

● A wide range of options: such as feeder, feeder, large hollow chuck, large spindle through hole, tool set, automated truss robot.

● The machine adopts modular design, with different customer product requirements, select different functional equipment, can quickly realize the automation device to meet the needs of customers.

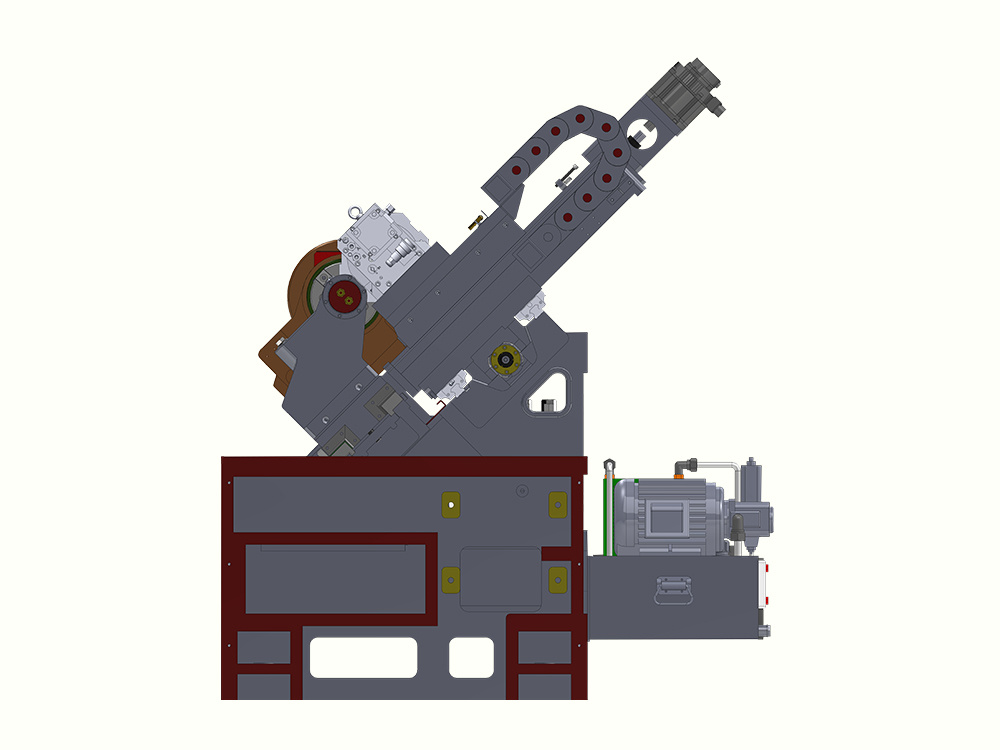

Rolling guide

High precision linear rolling guide, improve the moving speed, greatly reduce the non-cutting time. Imported ball guide rail, high positioning accuracy, less wear, can maintain accuracy for a long time, fully improve productivity, to ensure its processing stability.

45° overall tilt bed design

High-speed quiet ball screw, improve machine accuracy, ensure its processing stability, high positioning accuracy, less wear can maintain accuracy for a long time.

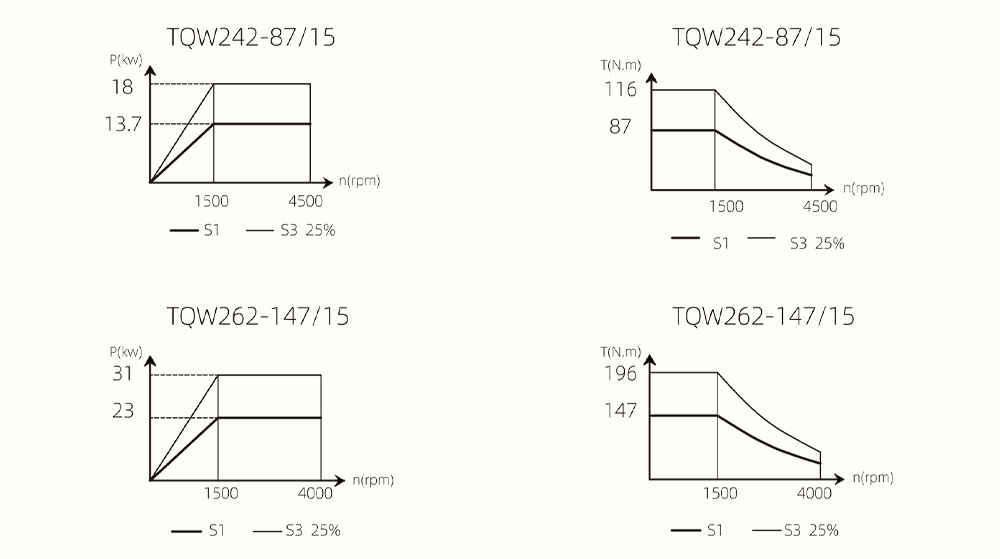

Spindle power torque diagram

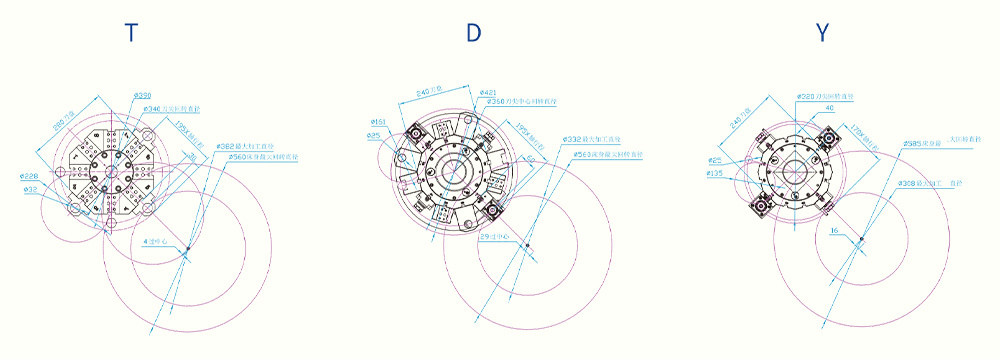

Tool interferogram

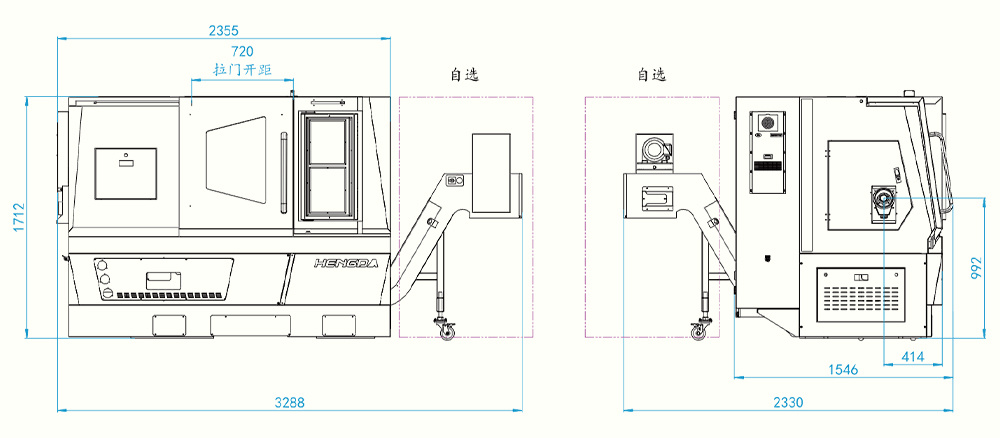

Outline dimensional drawing

| Items | Unit | HIL 40/5-T500 | HIL 40/5- D500 | HIL 40/5-Y500 | HIL40/6-T500 | HIL40/6-D500 | HIL40/6-Y500 | ||

| Processing Range |

Max.Swing dia.on Bed | mm | 560 | 560 | 585 | 560 | 560 | 585 | |

| Max.Cutting dia. | mm | 382 | 332 | 308 | 382 | 332 | 308 | ||

| Max.Cutting Length | mm | 485 | 473.5 | 469 | 475 | 463.5 | 459 | ||

| Max.bar dia.can pass | mm | 45 | 45 | 45 | 52 | 52 | 52 | ||

| Spindle | Max.Spindle Speed | rpm | 4500 | 4500 | 4500 | 4000 | 4000 | 4000 | |

| Spindle Type | ISO | A₂-5 | A₂-5 | A₂-5 | A₂-6 | A₂-6 | A₂-6 | ||

| Spindle Thru-hole dia. | mm | 56 | 56 | 56 | 61 | 61 | 61 | ||

| Spindle Taper | - | MT 6# | MT 6# | MT 6# | Metric 70 | Metric 70 | Metric 70 | ||

| Distance from Spindle center to floor | mm | 992 | 992 | 1006 | 992 | 992 | 1006 | ||

| Tailstock | Tailstock travel | mm | 85 | 85 | 85 | 85 | 85 | 85 | |

| Tailstock Taper | Morse | 4# | 4# | 4# | 4# | 4# | 4# | ||

| XYZ Axis | X/Z Travel | mm | 195/500 | 195/500 | 175/500 | 195/500 | 195/500 | 170/500 | |

| Y Travel | mm | / | / | ±35 | / | / | ±35 | ||

| X/Z Rapid feedrate | m/min | 30/30 | 30/30 | 30/30 | 30/30 | 30/30 | 30/30 | ||

| Y Rapid feedrate | m/min | / | / | 15 | / | / | 15 | ||

| Tool Turret |

Tool Positions No. | - | 8 | 12 | 12 | 8 | 12 | 12 | |

| Turret Type | |||||||||

| Tool holder Size of Cylindrical turning tool | mm | 25x25 | 20x20 | 20x20 | 25x25 | 20x20 | 20x20 | ||

| Tool holder Max.dia. of Boring hole turning tool | mm | 32 | 25 | 25 | 32 | 25 | 25 | ||

| Accuracy | Positioning accuracy | X/Z | mm | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 |

| Y | mm | / | / | 0.006 | / | / | 0.006 | ||

| Re-Positioning accuracy | X/Z | mm | 0.004 | 0.004 | 0.004 | 0.004 | 0.004 | 0.004 | |

| Y | mm | / | / | 0.004 | / | / | 0.004 | ||

| Total Power Capacity | kVA | 16 | 18.5 | 19.5 | 22.5 | 24.5 | 25.5 | ||

| Machine Size(L×W×H) | mm | 3290×1540×1710 (Right Side chip removal)/2355×2355×1710 (Rear chip removal) | |||||||

| Machine Weight | kg | 3400 | 3500 | 3600 | 3400 | 3500 | 3600 | ||

| CNC Controller | - | KND (SYNTEC/GSK/FANUC/SIEMENS Optional) | |||||||

| Spindle Motor Torque | N.m | 87 | 87 | 87 | 147 | 147 | 147 | ||

| Servo Motor Torque X/Z | N.m | 9.6 | 9.6 | 9.6 | 9.6 | 9.6 | 9.6 | ||

| Servo Motor Torque Y | N.m | / | / | 4.2 | / | / | 4.2 | ||

| Hydraulic Chuck | inch | 6" | 6" | 6" | 8" | 8" | 8" | ||

| Chip Conveyor | - | Right Side (rear chip removal optiontal) | |||||||

CNC lathe is one of the widely used CNC machine tools. It is mainly used for cutting the inner and outer cylindrical surfaces of shaft or disc parts, inner and outer conical surfaces with arbitrary cone angles, complex rotating inner and outer surfaces, cylindrical and conical threads, and can perform groove cutting, drilling, expanding, reaming, and boring.

Relevant information

这里是标题一h1占位文字

LEAVE US

A MESSAGE